THE STORY

shot & cut by Pianura News TV on January 2012 with interviews to Annito Quaglia and Piero Gabrieli on the history and the future of Molino Quaglia

BITTING THE GRAIN

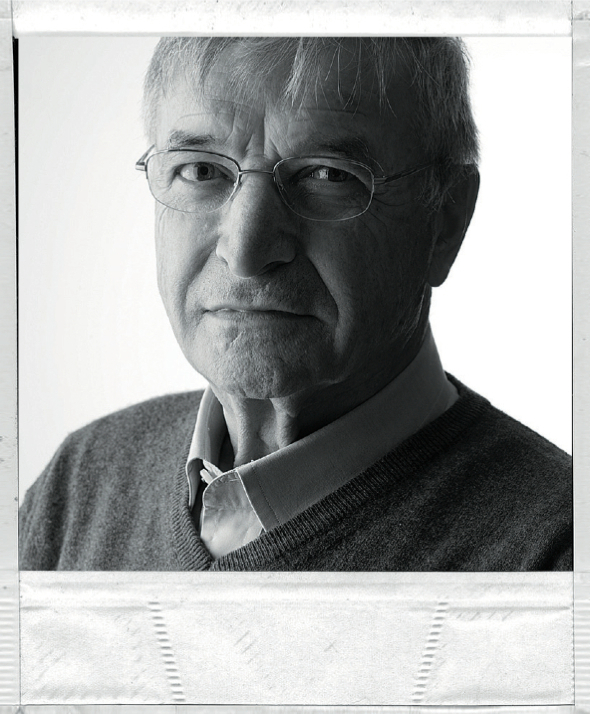

Is it possible for technology and tradition to live together over time? Yes, if they co-exist in a person's mind and temperament. In this case that person is Annito Quaglia, who lived through an era when wheat was chosen from experience matured through instinct, a ferryman towards the future of a company that has grown on the market little by little, committed to the same values as when it was still a small wooden mill on the Adige river.

The art he learnt from his father Angelo resulted in the school where his children Lucio, Chiara and Andrea trained. Today, the latter run the company on a daily basis, not only in contact with the numbers, but above all with the realities of the market: because, regardless of its expansion, Molino Quaglia remains a family company.

The state-of-the-art machines that keep an eye on each grain of wheat, from its arrival in the silos to its departure as flour, are controlled by software based on parameters that rely on a thorough knowledge of stone grinding. Knowledge that has developed over 4 generations of millers, which makes the difference on today's market with the first, unique line of stone-ground common wheat flour that boasts the cleanliness and consistent standards of a certified industry and skilfully selected wheat as taught by Annito.

All the flour that comes out of Molino Quaglia features the perfection of an exemplary industrial process, and the taste of when the best wheat grains could only be recognized by biting them.

“Our mill has grown over the years. And I realize this every day when I wander through the white passageways among the noise of the machines milling the wheat. Then I come out into the yard and as soon as the door closes behind me I can't hear any more noise.” This is Annito Quaglia speaking, getting on for 80 but probably not showing his age even in 20 years' time, from the third generation of Molino Quaglia, who has ushered his father's artisan company into the complex world of industrial milling. “And yet when I do enter that deafening noise and I see the wheat being shot into tubes on seven storeys, I understand that sometimes people know very little of what we're doing. Just like the noise of the mill, which others can't hear from outside.” Which is why Annito Quaglia, master miller par excellence, but a man of few words, accepted our invitation to talk about the activities of his mill. “Our story is that of a family who work with attention to detail, but always looking to raise quality.”

I ask whether today's flour has lost anything compared to the kinds he processed by hand when he was young. “I began my work by learning the stone-grinding technique from my father Angelo. He taught me how to cut the millstone to get the right flour, according to the type of wheat and what the baker wanted to use it for. Just think, that after the war my father and I prepared particular kinds of flour for pasta, bread and cakes, when other mills were only producing generic flour with scant experience in selecting wheat. That's right, because even today our ability to choose the right kind of wheat, without compromising on price, is decisive in guaranteeing our customers the quality they expect.”

I press him by asking again whether today's flour has lost anything compared to that of the past. Annito smiles at me good-humouredly, “Ours certainly hasn't!” And he adds, “Of course, over time the market has demanded types of flour that are increasingly refined, whiter, more suitable for modern bread and cakes. Today, however, there is a return to tradition, both in bread and cakes, and so our stone milling techniques are more fashionable than ever, to the extent that we have gone back to using stone grinding.”

I like this statement, so I urge him to go on. “Have you heard of our Petra flour? If you open a sack of Number 9 , its smell already makes you anticipate the taste of bread. And the wheat aromas of Number 5 will still be intact and strong in breakfast biscuits. I can assure you that this will also come as a surprise to those pastry makers and chefs who already use our technical flours, because they're going to get a noble flour with an unparalleled taste.”

I wonder out loud whether these new kinds of stone-ground flour are easy to work with. “Pastry makers and chefs who make quality their motto know that good food doesn't just happen by accident. The technology we started using in our mill allows us to stone grind flour to obtain varieties that are as easy to work with as modern ones. ”

“But can you still find older kinds of wheat?”, I ask as I watch him plunge his hand into a pile of golden grains that skitter between his fingers. “It isn't right to speak of past and present wheat. Wheat varies from year to year because it's nature that makes it, but if you can understand its potential use, then my answer is that we still select wheat in the same way as when I was a young student of my father Angelo. We go for the harvests that are most suitable to maintain the quality of our flour. And just to be sure, I still do this by biting a grain.” Did I hear right? By biting a grain? “It’s a family technique," Annito smiles, “that I learnt from my father Angelo, to assess how flour would behave during kneading by biting grains and tasting them. You know, at that time, today's machines didn't exist and the art was cultivated from experience and a spirit of observation.”

I'm forced to stop him there, because this is a burning topic and I have other curiosities to satisfy. I turn round and point to a building across the road (by the way, I'm in a tiny agricultural village whose square is overlooked by a church and the mill, with the enchanting Euganean Hills in the background and the air still redolent of wheat reaping). “What you can see in front of the new plant is our old mill. My sons have restored it to house "Il Laboratorio", our research and training centre. I like the name, because it expresses our constant desire to look for new directions in our work. Come with me, I'll show you the technology room.” We go there and, in a room where modern equipment stands out against a background of old flour bins and a series of orange pipes, I see a group of people in white shirts working with great concentration.”Let's keep quiet; they're studying the reactions of the live strains of mother yeast. There's so much life in that bowl, and that's where real bread comes from.” So what have they discovered by observing those yeasts? “They've discovered that ever since they started feeding on our stone-ground flour, they make better bread and cakes."

Is that a joke? I've no idea, but underscored by that intense gaze and pronounced with the eager perkiness of a kid, it can only be true!

Complete interview given by Annito Quaglia in 2009 to the magazine Dolce e Salato - Gruppo Food.

CONTATTI

GRAZIE A

@ 2012-2018, PiCi. In concessione ad Arte Innovativa degli Alimenti srl via Roma 49 - Vighizzolo d’Este (PD)